Then, when you approach the reorder point, Cogsy will send you a replenish alert. Let’s say one SKU’s optimal quantity is 200 units, and you have 25 units available right now. But because there’s a discrepancy in your data, your inventory management software shows you only have 30 units on hand. Cogsy, on the other hand, tracks inventory levels 24/7 and considers how this data will affect your brand’s forecasts in real-time.

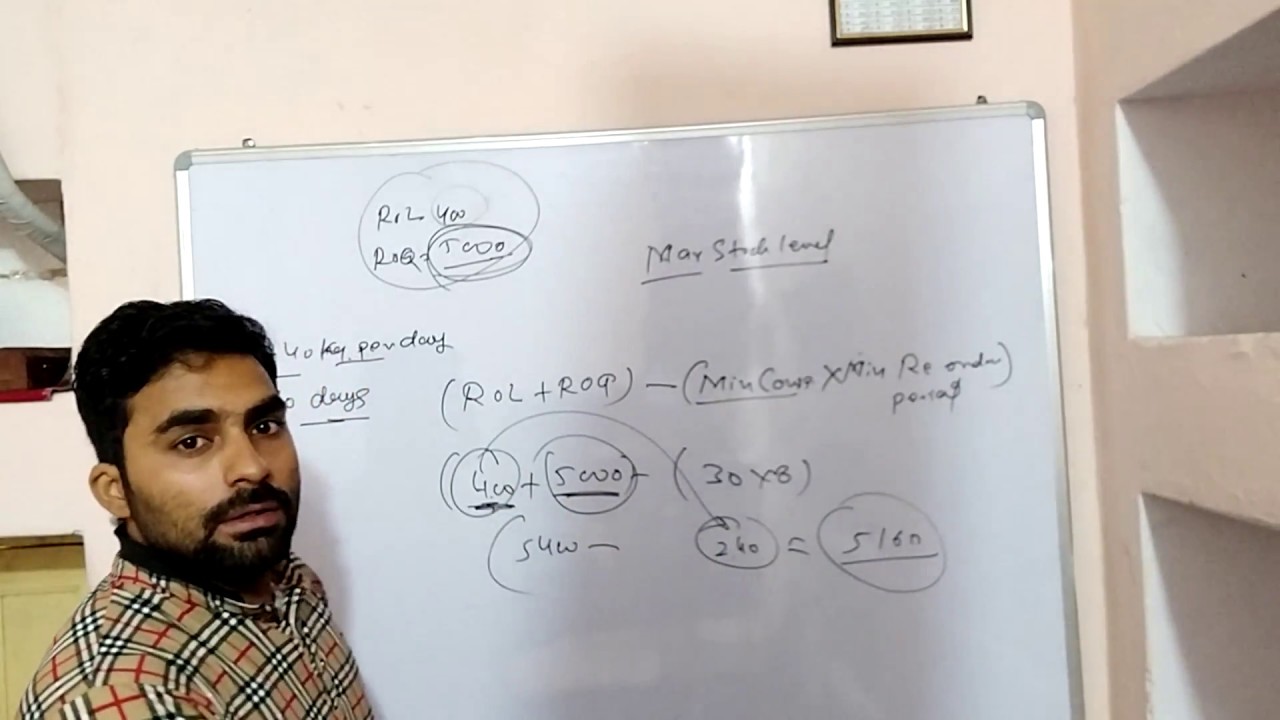

Calculating Min and Max Stock Levels:

- An item’s reorder point, or the point at which you order additional stock, may vary based on seasonal or economic factors.

- At Interlake Mecalux, we are specialists in pallet racking, picking shelves, automated warehouses and logistics software.

- Let’s say one SKU’s optimal quantity is 200 units, and you have 25 units available right now.

- Another solid step is to invest in Inventory Planner and use this dynamic tool to stay ahead of demand and avoid supply chain disruptions.

- The modular MACH architecture of Actindo Core1 – consisting of microservices, API-first, cloud-native and headless components – also facilitates the connection of new sales channels.

The software further streamlines the reorder process by automatically generating alerts and purchase orders upon reaching minimum stock levels. Its integration with supplier databases enhances communication, ensuring swift replenishment and centralized control over multiple inventory locations. Accurately calculating your minimum and maximum inventory levels directly impacts your eCommerce profitability. According to Statista, over half of global e-shoppers reported being unable to purchase products due to items being out of stock in 2022.

Replenish on time and keep inventory levels balanced 🔄

Apply inventory management methods to refine your inventory strategies and reap the benefits of efficient inventory management. The higher the service level requirement and the greater the demand variability, the higher the safety stock requirement. Plus, we break down the formula for making sure your inventory is in line with demand, the installation, and the steady growth of your company. Here’s an overview of retail stock management and strategies for maintaining the optimal inventory level of your products.

Maximum inventory levels

Get in touch — we’ll provide you with a personalized demo of Easy WMS with all the control and stock management functionalities you need. In this formula, Z represents the service rate, which can be calculated according to certain criteria. The standard deviation of demand measures the dispersion of sales in relation to the average.

Future trends and opportunities

Trying to adjust it to an increasingly complex reality lies in integrating specialised logistics management software and basing decisions on measurable data. A minimum stock level is a threshold value that indicates the level below which actual material stock items should not normally be allowed to fall. Utilize inventory aging to effectively categorize your eCommerce products. Fabrikatör automates the entire process, keeping your stock levels consistently optimal.

Managing Stock Levels: Strategies and Formulas

As a result, employees and storage locations are not overloaded with unnecessary products or are unable to increase sales due to lack of inventory. As a result, a company can quickly increase its sales cycles, how to professionally ask for payment from clients template fill rates, and customer satisfaction. By having a firm grasp of current stock levels and how much to reorder, a company can effectively build its supplier relationships and supply chain strategy.

Not only is inventory the primary source of revenue and expenses, but it’s also central to all other areas of operations, including supply chain management, sales, and customer service. Determining optimal inventory levels — and finding the most efficient way to maintain them — is a primary factor in a company’s success. The Min/Max method is based on a simple principle of determining minimum and maximum stock levels. You cannot maintain appropriate stock levels without accurately forecasting demand. If your demand forecasts are accurate, you can sell products as they come into stock. If you overestimate demand, you may wind up with unsellable inventory and a net loss of revenue.

In this post, we’ll cover how is email useful for eCommerce businesses and how you can leverage it to better engage with your audience. For example, if a bookstore sells around 50 copies of a particular novel every month, that’s the normal consumption. We’ll review how they work, specific formulas, and hypothetical examples of each in an ecommerce context. Additionally, if a purchase order placed with a supplier is set up for automatic dispatch, the company loses out on the advantages of goods consolidation and groupage. Visually, therefore, they take the form of a sawtooth graph, with peaks representing the purchase of inventory and valleys showing the dispatch of these goods from the warehouse. Our writing and editorial staff are a team of experts holding advanced financial designations and have written for most major financial media publications.